Environmental Policy

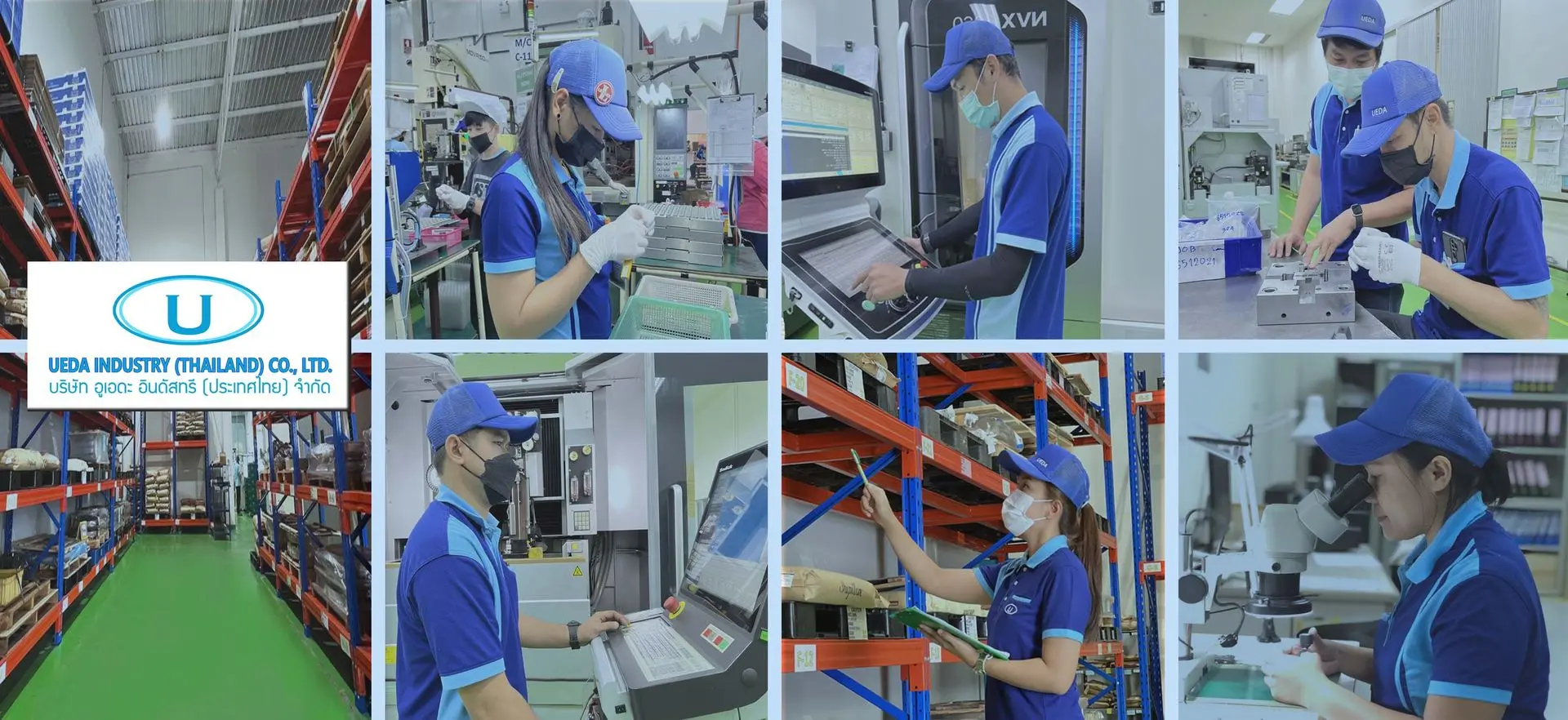

Ueda Industry (Thailand) Co., Ltd., a manufacturer of plastic parts for vehicles, electronic products, and plastic injection molds, as well as providing high-quality international-standard services, recognizes its environmental responsibility to employees and the community. The company has implemented an environmental management system in line with its business operations, adhering to ISO 14001 standards, and is committed to the following practices:

- Establish and continuously improve the environmental management system in accordance with the requirements of ISO 14001

- Comply with laws, commitments, and other requirements related to the company's environmental issues

- Develop and review environmental objectives and targets to ensure continuous improvement and alignment with environmental commitments

- Efficient use of resources by promoting reuse, recycling, and substitution

- Reduce waste from various processes in product manufacturing

- Manage waste and garbage appropriately

- Reduce energy consumption in various forms to combat global warming and conserve resources

- The company is committed to regulating the use of chemicals, raw materials, and products to prevent and control hazardous substance contamination, ensuring compliance with customer standards and RoHS requirements

- Conduct training to educate and raise awareness among employees at all levels about the importance of environmental preservation in the company's activities

- Disseminate environmental policies, objectives, and goals while encouraging information exchange with customers, suppliers, and the public

Ueda Industry (Thailand) Co.,Ltd.

Managing Director: Tomohiro Ueda

Quality Policy

The management has demonstrated its commitment to adopting standards by establishing the company's quality policy. This policy serves as an expression of that commitment and is communicated to all employees to ensure understanding of objectives, requirements, expectations, and intentions for applying the management system. It provides a framework for setting quality objectives, targets, performance indicators, and meeting customer needs. The company's quality policy is as follows:

"Achieve customer satisfaction, ensure on-time delivery, and continuously improve quality"

( Customer Satisfaction , Delivery on time and Continuous Quality Improvement )

ISO Certificate

Ueda Company is dedicated to enhancing its management systems for efficiency in accordance with international standards. Achieving ISO certification underscores our commitment to quality and the highest level of customer satisfaction. Our goal is to build trust and confidence among customers and partners through reliable, high-quality operations across all processes

ISO14001:2015 CERTIFIED

IATF 16949:2016 & ISO 9001:2015 CERTIFIED